The majority of the house framing has been completed. Although some framing is still yet to be installed, mainly the roof structure, it is now time to change gears and concentrate on a new task; pouring of the second-story floor.

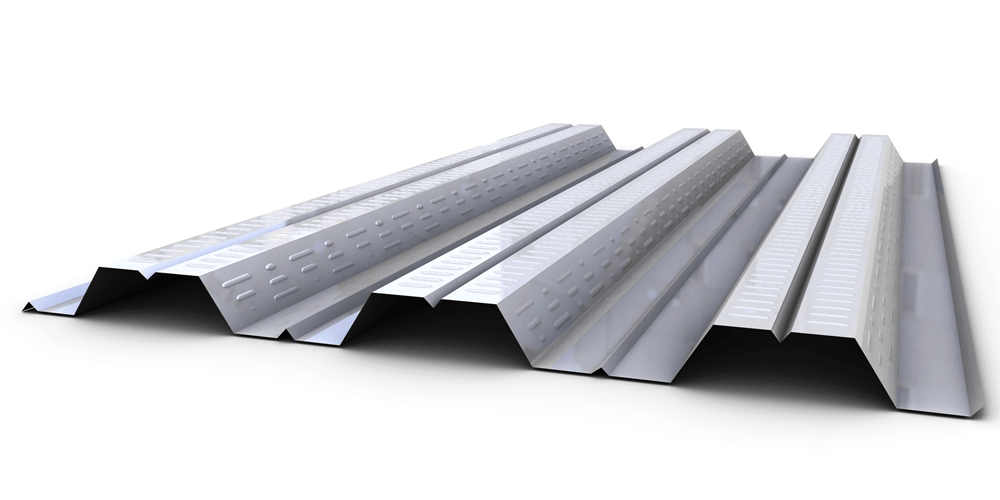

Preparation for this pour begins with constructing the form. Timber is used to frame and secure the perimeter, while a product called Novalosa is laid across the metal cross members, covering the entire footprint of the second-story floor. Novalosa is a galvanized steel sheet, 0.65mm thick (approximately 1/32″), featuring trapezoidal corrugation. Positioned directly beneath the concrete, it serves as permanent formwork, helping to create a strong, composite slab. Its design also reduces the volume, and therefore the overall weight, of concrete required. Rebar mesh is placed on top of the Novalosa and the form is ready.

With the form in place, the workers can now begin pouring the floor. However, this is another tremendous task, as once the workers begin the pour, it needs to be taken to completion in the same day. This allows the creation of a single, continuous slab that maximizes structural integrity and helps ensure a more crack-resistant and even surface after curing. And Marco, our ever-vigilant architect, says that day is today!

Workers begin by combining cement, aggregate, and water to make the concrete; this time aided by a gasoline-powered drum mixer, as time is a major limiting factor. The concrete is then poured into a large bucket and hoisted by rope, pulley, and Marco’s truck to the second story.

From here it is transferred to wheelbarrow and moved to the appropriate spot for leveling and screeding.

Pictures of the completed pour will have to wait until the next post as the guys all worked well into the night to make sure the job got finished. But, please check out the video below to get a sense of how much work went in to completing this step.

Wow that’s starting to look like a real house. I never knew how they did the cement floors between levels. Very interesting to see.

I was unsure as well how they would support the concrete for the second floor. This post has covered one of the more interesting aspects of the home build so far.

Crazy! Very different from construction in US. Any idea why they go for steel infrastructure and concrete pours on 2nd floor ? US is mainly just wood construction as far as I know! One thing is for sure , that thing will be sturdy af. Kris will have a nuke grade bunker.

There are several reasons why wood is not commonly used here. Climate and humidity makes it more susceptible to rot in many areas of Ecuador. Concrete and brick are much more resistant to pest, flood and earthquake damage and are also noncombustible. Trees that make appropriate lumber for building are not as widely available as compared to the United States, making it a much more expensive resource. And culturally, home building in Ecuador was heavily influenced by European settlers, which favor a concrete and brick construction.